| Type | Product List |

|---|---|

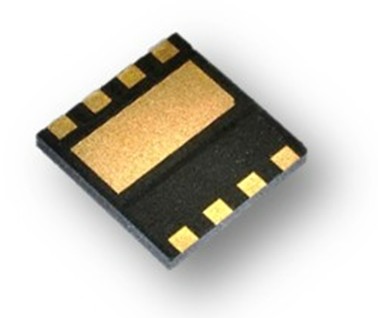

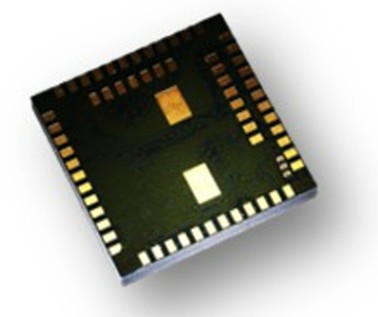

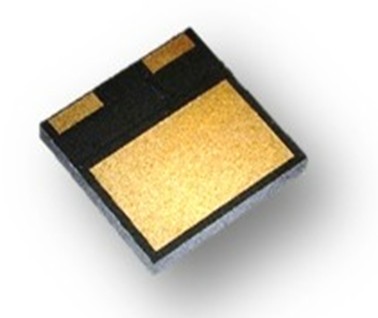

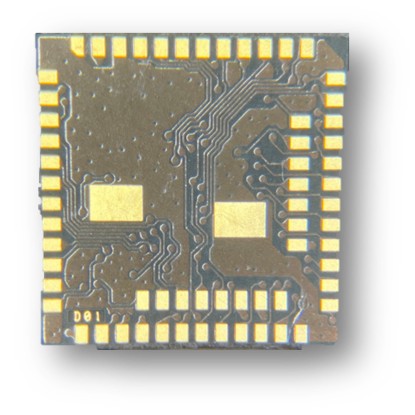

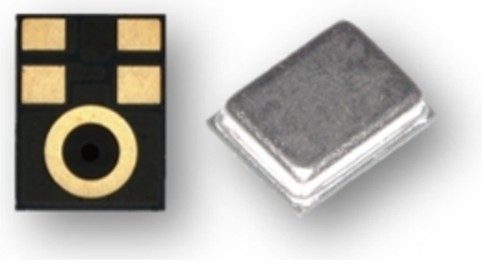

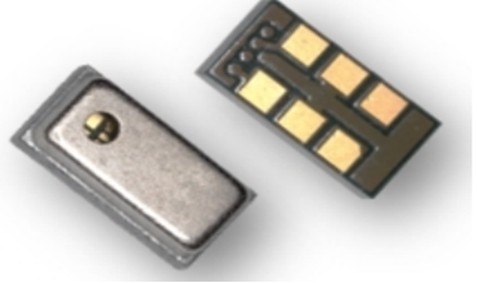

| Lead frame Packing | DFN/QFN |

| SOP/TOPS | |

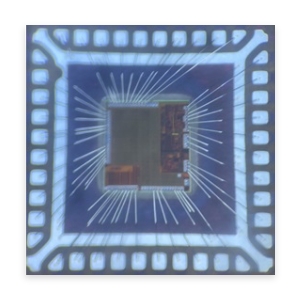

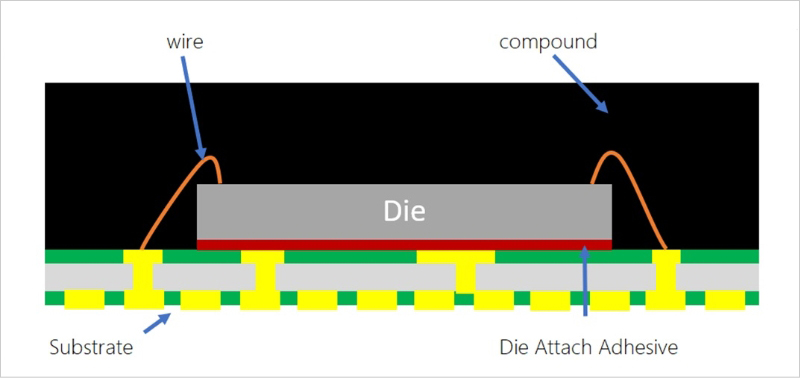

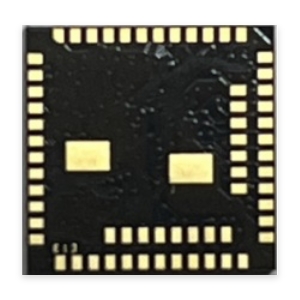

| Substrate Packing | LGA |

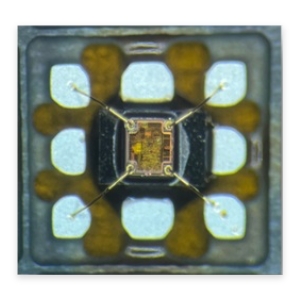

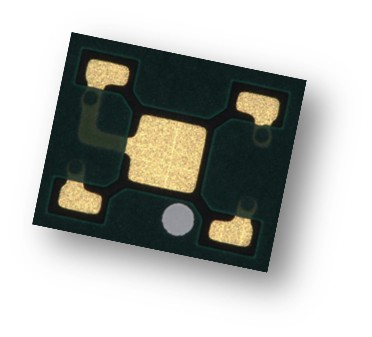

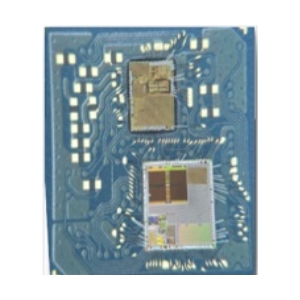

| Advanced Packing | MEMS |

| Opto Sensor Module | |

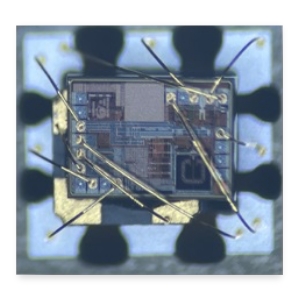

| LGA Module | |

| Fingerprint Module |

| Package Thickness | Package Size | Lead Count |

|---|---|---|

|

0.38mm 0.75mm 0.85mm 0.93mm 1.00mm |

2mm * 2mm | 8L |

| 3mm * 3mm | 12L、16L、20L | |

| 4mm * 4mm | 16L、20L、24L、28L | |

| 5mm * 5mm | 16L、24L、28L、32L、40L |

Package thickness and size, single chip or multiple chips can be customized according to customer needs.

Package thickness and size, single chip or multiple chips can be customized according to customer needs.

All devices are based on customer design and requirements.

Reliability testing must be performed upon customer request and consultation.

If there are no special requirements, it shall comply with the conditions of Jedec Std MSL 3.

| Test Item | Test Method | Test Condition | Equipment | Remark |

|---|---|---|---|---|

| Temp. & Humidity Storage | JEDEC-STD-22 A101 |

Ta=85℃, 85%RH | Temp & Humid Chamber | ● |

| Pressure Cooker | JEDEC-STD-22 A102 |

121°C/100%R.H. 29.7 psia |

Pressure Cooker Chamber | ▲ |

| High Temperature Storage | JEDEC-STD-22 A103 |

Ta=150℃ | Oven | ● |

| Temperature Cycle | JEDEC-STD-22 A104 |

-65℃ ~25℃ ~150℃ ~25℃ 30min 5min 30min 5min |

Temperature Cycle Chamber | ▲ |

| Precondition Test | JEDEC-STD-22 A113 |

MSL 3 | Oven, Temp & Humid Chamber, IR Reflow Oven |

● |

| HAST | JEDEC-STD-22 A118 |

130°C/85%R.H. 33.3 psia |

Temp & Humid Chamber | ▲ |

▲: Outsourcing testing

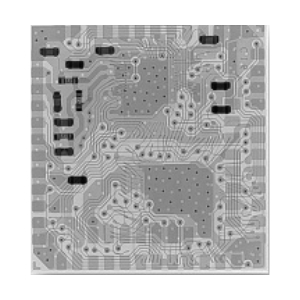

We are professional packaging and testing factory focusing on QFN / DFN / LGA / SIP and other products.

Suitable for small and medium-sized orders, with rapid production line modification and line change mode. We can work with customers to research and develop products, and conduct process design and control for complex packaging types. Support emergency order production service. IC packaging combined with SMT module OEM production model. Use information management and standardized production to improve production quality and reduce production time.